HVAC, DUST COLLECTION, PAINT AND FINISHING

RELATED PRODUCTS PARENT

Pleated Air Filters

Disposable Air Filter Panels

HEPA Filters

V-Bank Air Filters

Rigid Cell, Box Style, Cartridge Air Filters

Bag Air Filters – Pocket Air Filters

Bulk Media – Rolls and Pads

Activated Carbon Air Filters

Metal Washable Air Filters

Paint Booth Filtration

Dust Collection Filters

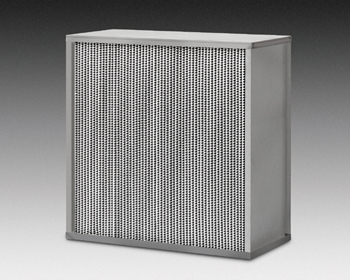

HEPA FILTERS

High Efficiency Particulate Air filters (or “HEPA”) is, unfortunately, a broadly used term to describe air filters for a variety of applications. However, many air filters that include the word ‘HEPA’ as part of their description may not meet the standard as it has been defined. At the time of writing, US government standards state that filters meeting the HEPA designation must remove 99.97% of any particle that passes across the filter media with a size of 0.3 micron. Additional standards stipulate that the filter must meet this efficiency with minimal pressure drop and maximum air flow when in operation.

HEPA filters are manufactured with a range of dimensions, frame materials/shapes, operating temperatures and air flow capacities. HEPA filters are carefully specified for each application, and this process requires expertise and care to be taken when selecting the correct part.

For the most demanding filtration applications, Ultra-Low-Particulate (ULPA) filters are also available, which are specified to remove 99.999% of particulate 0.12 micron or larger.

RANGE OF SPECIFICATIONS

Efficiency: 99.97% @ 0.3 micron up to 99.999% @ 0.12 micron

Media: Paper-like Glass Fiber, Polymer Sheets

Construction Materials: Aluminum Frames, Pressed Wood Frames, Plywood Frames, Plastic Frames, Aluminum Separators, Elastomer Gaskets, Media

Flow Rate: 250-3000 CFM

Sizes:

Standard Depths of 5 7/8″ and 11 1/2″

Various Standard Frame Sizes Available

All Custom Sizes Available