RELATED PRODUCTS PARENT

Pleated Air Filters

Disposable Air Filter Panels

HEPA Filters

V-Bank Air Filters

Rigid Cell, Box Style, Cartridge Air Filters

Bag Air Filters – Pocket Air Filters

Bulk Media – Rolls and Pads

Activated Carbon Air Filters

Metal Washable Air Filters

Paint Booth Filtration

Dust Collection Filters

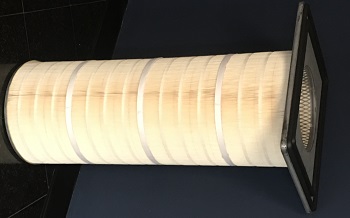

DUST COLLECTION FILTERS

Dust collection is a process used in many industrial and commercial processes to remove granular solid pollutants from exhaust streams or process-generated dust prior to venting into the atmosphere. Dust collectors can also used to maintain the quality of interior air in dust laden work environments.

While there are many different designs and sizes of dust collector systems, most systems typically include a blower, a filter, a filter cleaning system and a receptacle to hold sediment. Most commonly, dust collector systems will use either bag filters (in dust collector bag houses), or cartridge filters, depending on the requirements for the environment in which they are operating.

It is important not only to ensure that replacement bag filters or cartridges are sized appropriately to avoid bypass through the system, it is paramount that replacement filters are matched to the air quality requirements, operating temperature, moisture content and PH of the air flow. There is a wide range of media, efficiencies, and designs to dust collector filters, and the selection process for your replacement filter may not be straightforward. Our technical team can ensure that a replacement cartridge or bag filter is properly matched to your system, delivering the result that you require for your operation.

RANGE OF SPECIFICATIONS

Efficiency: Bag Filters Range from 95% to 99.98% efficient, Cartridge Filters range from MERV 8 to MERV 16

Media: 100% Synthetic Polypropylene – does not support microbial growth

Construction Materials: Metal Frames, Polyurethane Adhesion, Media

Flow Rate: Bag Filters range from 10-55 CFM,

Sizes:

Standard Depths of 12″, 15″, 22″, 29″ and 36″

Various Standard Frame Sizes Available